Products

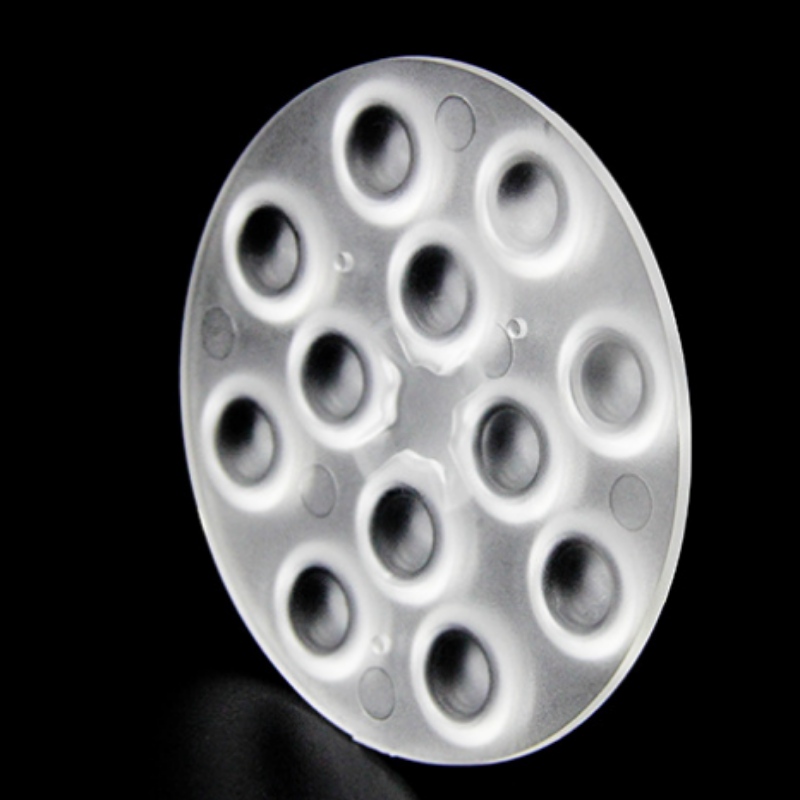

Led lighting fittings household products auto spare parts Medical accessoriesSporting goods Plastic mold

Five Advantages Of Products

- 1.Provide lifetime warranty for production mould. As long as we continue to manufacture your parts in our factory, we will maintain and repair tools as required at our expense

- 2.The main business includes: daily necessities, all kinds of mechanical accessories, security supplies accessories, all kinds of lighting accessories, auto accessories, printer accessories, speaker accessories, etc. it is a plastic injection manufacturer, plastic and aluminum die-casting mold manufacturer.

- 3.The company has more than 10 years of production experience, and the engineering department adopts advanced CAD / pre / UG software to assist the design. So that the quality and stability of the mold get the trust of customers, has been providing high-quality technical advice and warm and thoughtful service for new and old customers.

- 4.allows you to make design changes on production molds. Icomold engineers will coordinate with you to change CAD files and rework the mold accordingly. Before production, you will receive revised samples for your approval.

- 5.Instant tooling and parts quoting > low cost, fast build and high quality production > icomold lifetime warranty for production tooling > Online Project Management > trouble free parts modification > no size limit > any commercially available materials and surface finish

Product Details

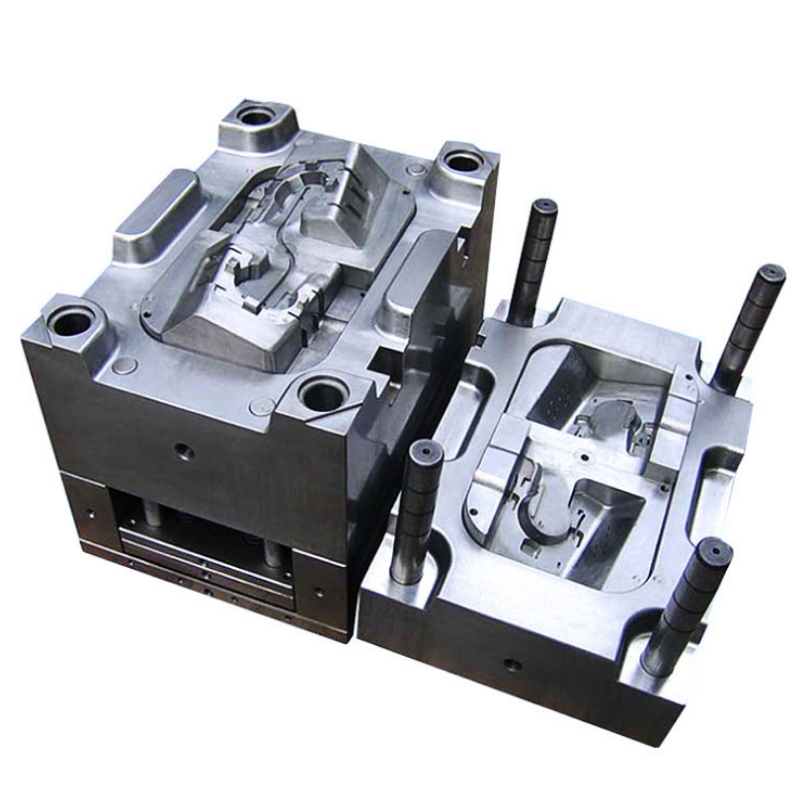

The following factors should be considered in the design of injection moulds

Mold and injection molding processing cost is a topic that every enterprise is very concerned about.Injection mold manufacturers must consider how to achieve low cost and high efficiency in the mold design process.The following factors should be considered in the design of injection moulds:

1. Injection molding cost

According to the size of the machine, the number of holes in each beer product determines the product ranking method and the number of holes.The more cavities produced, the lower the injection cost.Because in the injection molding process, cost accounting is calculated by the number of holes.

2. Product appearance

According to the product appearance requirements, determine the parting surface.Parting surface position should be conducive to mold processing, exhaust, stripping, etc.The more products there are, the greater the potential for cosmetic problems.

3. Nozzle mode

Determine the shape, size and exhaust direction of the main and branch channels.Hot runner mold cost is high, but the nozzle cost is saved.Each method has its pros and cons, depending on the user's choice.

4. Product demoulding

Determine the ejection mode and arrange the ejection pin position.The higher the ejection position, the higher the die cost.

The injection mold design also needs to consider the product shrinkage and injection time to determine the cooling or heating form and the location of the cooling channel.Considering the service life of the die, determine the hardness, thickness and size of the die material.And determine the shape of the resulting partial splitting and linear cutting structure.As long as the above steps in all aspects of a good combination, comprehensive analysis and balance, can effectively save costs.

Dongguan LIXING PLASTIC & Metal Products Co. , Ltd.

Contact Person: yangkuizhen

Telephone: 13686076396

Landline: 13686076396

Company Address: 18 Jinxia road, Shixia village, Dalang Town, Dongguan

Website: lixing.us764.com

Previous: auto parts